Pedro Pacheco is a GIS Officer and Drone Pilot at The HALO Trust in Angola. Pedro has been working with Routescene, an ARPAS-UK member, since 2021 flying UAV LiDAR missions across minefield sites to inform mine clearance planning. This article explains the work Pedro undertakes, it describes the conditions he and the drone team operate in, the equipment they use and the challenges they face.

Q. What drone are you using for this work?

A. We are using a DJI M600 Pro, which is a hexacopter capable of lifting a 5kg payload for approximately five minutes, and automated flights are executed using the DJI Pilot Application.

Q. What UAV LiDAR system are you using?

A. We are using a Routescene UAV LiDAR System. The unit contains a 16 channel LiDAR sensor, capable of collecting approximately 600,000 points per second, a GNSS/INS sensor and data storage to capture 12 hours of data. The system was designed to be resistant to in-flight vibrations and handling by users. t doesn’t require a mobile or internet connection to operate which provides us with operational autonomy and data security. GNSS data is collected for the post processing of the trajectory to ensure the data is as accurate as possible.

Q. Describe a typical day for us.

A. Work usually starts the day before the field surveys take place. This day focuses on planning and includes charging batteries, checking equipment and preparing the flight plans and risk assessments.

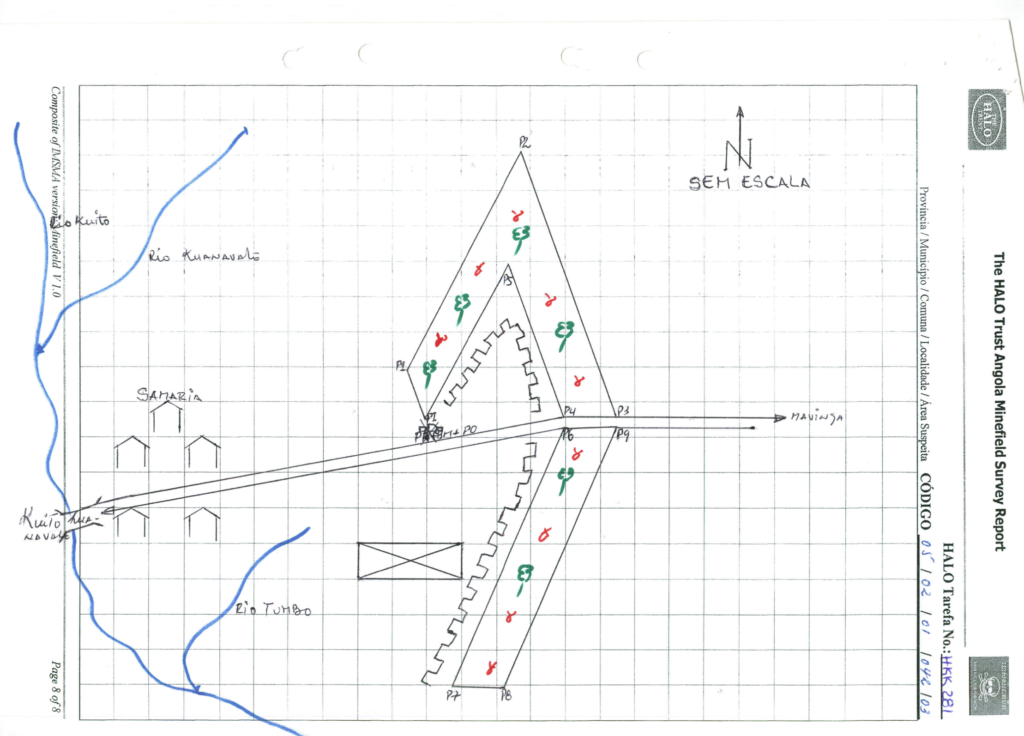

The drone team heads to the field survey site in a Kamaz down sandy roads. Depending on the location and the condition of the roads this journey may take 1-2 hours for many missions or up to 12 hours if taking the sandy roads down to Mavinga. In the field a suitable location is identified for setting up the drone, the UAV LiDAR system and the base station. The missions are flown and the data is downloaded and processed once back in the office.

When a survey mission is in a more remote location and will take more than one day to complete, the team will stay in one of HALO’s remote demining camps. These camps are built in safe areas that have already been demined and offer safe access to our clearance tasks. These camps are made up of large tents for the deminers and drone team to sleep in.

Q. What have been your biggest challenges as a Drone Pilot whilst undertaking these UAV LiDAR surveys?

A. We have faced many challenges during data collection. Whilst undertaking missions the most dangerous challenge has been the uncleared land which poses a threat to life to the drone team. This can drastically reduce the choice of suitable drone take-off and landing sites and locations to site the base station. Once we had to use the cleared narrow sandy road for both drone take-off and landing sites and to site the base station, having to move the equipment to let vehicles past.

Limited access to power to recharge batteries during missions is constantly a problem. We have to recharge batteries each evening at the camp. Of course, this can limit the number of flights we can complete in a day, typically 2 per day. Occasional power cuts can lead to further issues with charging between flights. Additionally, the teams are often working in regions that do not have mobile coverage.

Q. What distances are you covering to complete missions?

A. Many of the minefield sites in Angola are 20-30km long and the maximum distance thatthe DJI M600 Pro can fly is 1-1.5km. The travel to site from camp each day can take 2 hourson average due to the terrain and conditions, which also limits the number of missions wecan complete.

Q. How many drone LiDAR surveys have you performed to date?

A. We have completed over 40 missions to date. The number of missions we can manage in one month varies according to the local seasonal conditions. Currently we are undertaking about 6 missions per month. However, this is likely to decrease between October and May due to the Angolan wet season. The optimal time of year for surveys is between May and September when weather and road conditions are best.

Q. How much mine clearance work is still left to do in Angola?

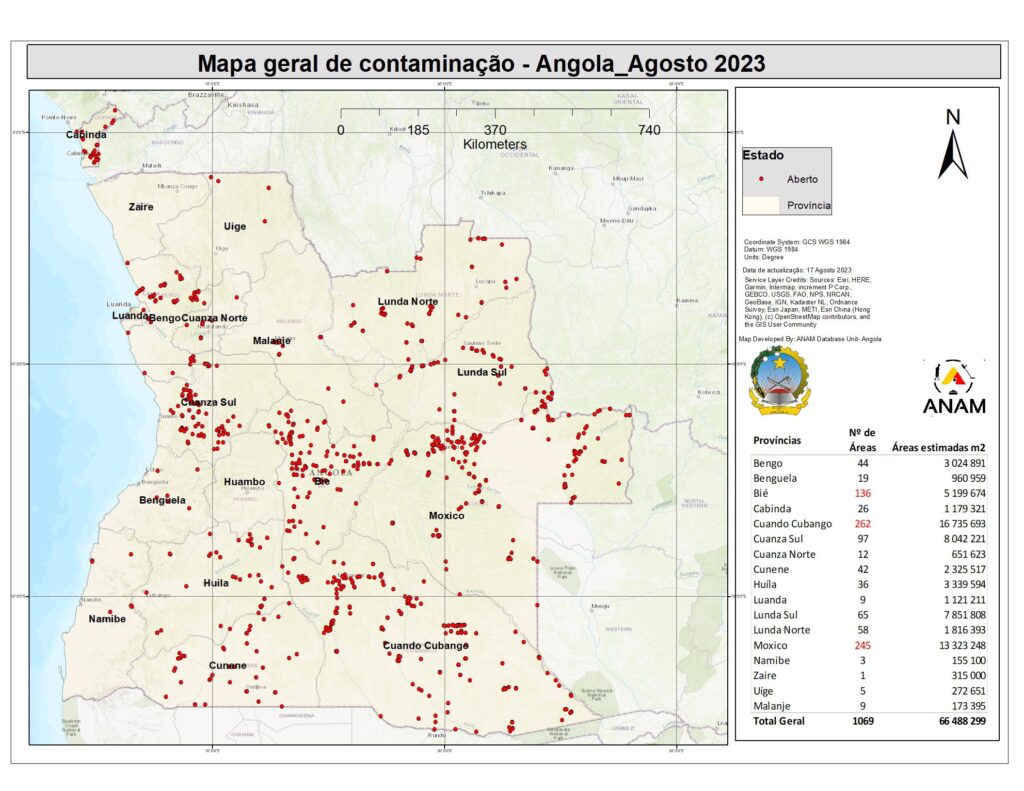

A. Currently there are 1069 known minefields across Angola, totalling an area of 66,488,299m 2 . The map below provided by ANAM (Angolan Mine Action Authority) shows the scale and location of the known minefields in Angola. The Government of Angola’s aim was to clear the country by 2025, but even with additional resources and scaling up of demining operations there are still many years of clearance ahead.

Q. How have you analysed the data you have collected?

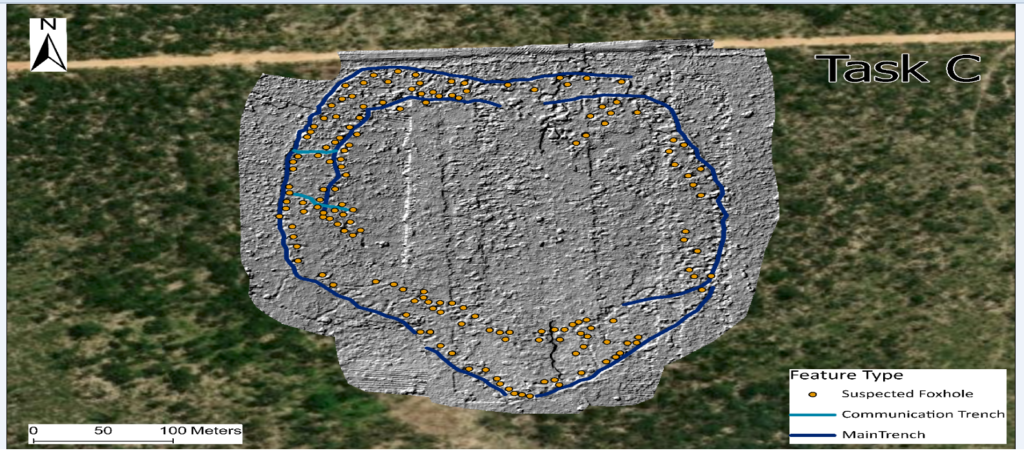

A. We use a specially designed LiDAR post-processing software application, LidarViewer Pro created by Routescene, which we use to clean and process the data. The outputs are Raster files and we load these geotiffs into ESRI’s ArcGIS, then visually inspect the files to identify the location of battlefield features such as trenches, foxholes, shell scrapes and craters, which are indicators of minelaying. We manually annotate the files and produce pdf maps to aid the operations team with the creation of clearance plans.

Q. What has been the impact of this work?

A. UAV mounted LiDAR has had a huge impact on HALO’s mine clearance work in Angola. This technology has provided us with invaluable information about minefields while we clear them or even before we start doing so. The resulting Digital Terrain Models (DTMs) have helped us to understand the terrain and identify the exact locations of potential hazards, which we would otherwise only have limited insight into. This includes the identification of previously unknown trenches, craters and bunkers, which all could indicate the potential presence of minefields. This information is then incorporated into our existing survey methods and the contextual knowledge of our experienced teams on the ground, who feed this into their planning and clearance operations.

On one minefield in Cuito Cuanavale in southeastern Angola we were working for several months to clear a long line of anti-vehicle mines until we believed we had reached the end of it. However, the UAV LiDAR imagery showed several craters from mines in an area far beyond our site which had been detonated because of nearby wildfires. The mine line had in fact continued but in a different direction we were not aware of. Had it not been for the UAV LiDAR results we would not have known about these craters and would have spent weeks or even months scouring the area for the remaining mines. Instead, our deminers could directly clear towards the craters to ensure the area was safe. This is one of countless other examples where this technology has allowed HALO to better target its’ precious resources to protect mine-affected communities and wildlife, and make this land safe for agriculture, access, development and conservation.

Q. How are you received when you travel around the local villages to survey the land?

A. HALO has operated in Angola since 1994 and as a result we have deep roots in the local communities where we have been working and recruiting from for many years. When we go out with a drone and the UAV LiDAR equipment to areas where there is a village we often gather interest, especially from children. In some instances the local community provides us with information that can be useful for targeting the team’s drone surveys.

Q. Tell us about other dangers you face in addition to UXO?

A. Other than UXO, we face very few dangers during our flights. The biggest issue we have faced so far is wildlife interference during a flight. This occurred whilst using a Mavic 2 Pro in a forested region… an eagle swooped down on to the drone while the drone was hovering before landing. We expect the bird thought the drone was a small bird that it could prey on.

About the authors:

Pedro Pacheco

GIS Officer and Drone Pilot, The HALO Trust

Pedro Pacheco is a GIS officer and drone pilot with The HALO Trust program in Angola. He focuses on the use of drone surveys for non-technical survey support to aid in clearance planning. Pedro graduated from Agostinho University with a bachelor’s in geography, with a focus on Satellite Image Processing and Geospatial Information Technology.

Emma Thomas

Director and Chief Marketing, Sales and HR Officer, Routescene

An experienced marketing specialist, Emma drives the commercial and strategic direction of the business. Utilizing over 30 years of business experience, Emma has cultivated a strong, recognisable Routescene brand, delivering marketing and business development activity to enter new markets, to expand product portfolios and to consolidate existing business.

17 November 2023